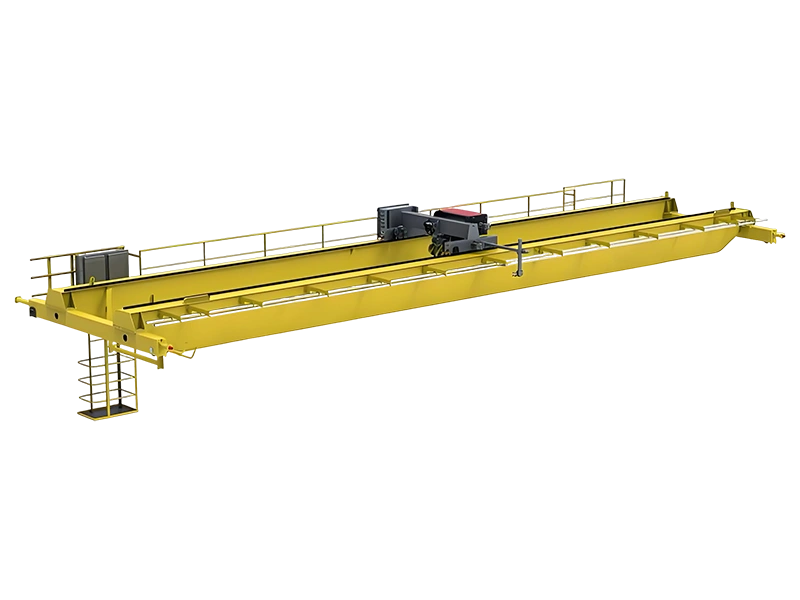

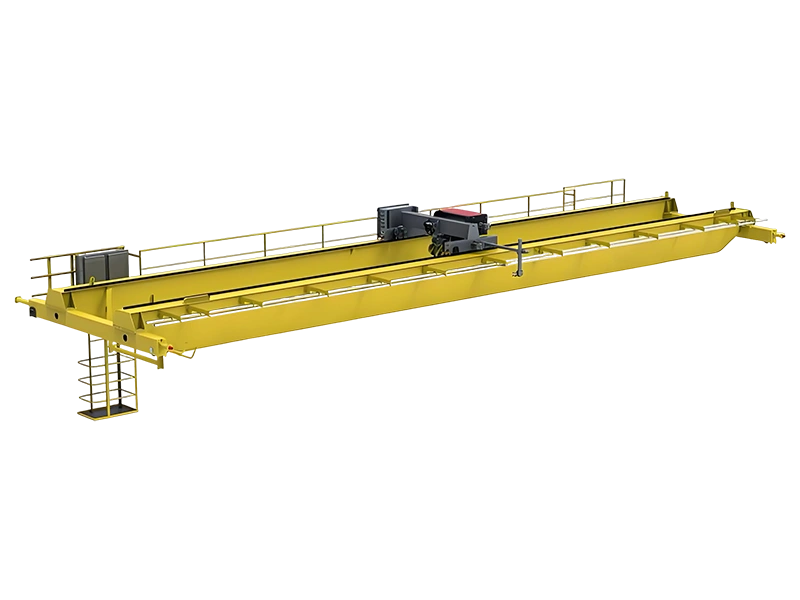

LH modelelectric Hoist Overhead Crane has such features astight dimensions,low build ing headroom,light dead weight and light wheel load. They are applicable to the transfer, assembly,check and repair as well as load and unload at mechanic processing workshop, subsidiary workshop of metallurgical mills,warehouse,goods yard and powerstation.They can also be used instead of common double-girder overhead crane at production workshop in light textiles orfood industry.It hastwo kindsof classification,that is,light and medium.The working ambient temperature is generally-25℃~40℃ . It is forbidden to work in environment with combustible,explosive orcorro sive media. Two operating methods,namely,on floorand in the drivers cabin, have been designed for such kind of crane.The cabin is divided into open-style and closed style.

| QSMLGn rated lifting capacity | t | 16/3 | ||||||||

| operational method | m/min | ground controlling;room controlling | ||||||||

| Speed | main.hook lifting | 3.5(0.35/3.5) | ||||||||

| Aux.hook lifting | 8(0.8/8) | |||||||||

| crab travelling | 20 | |||||||||

| trolley travelling | ground | 20;30 | ||||||||

| room | 30;45 | |||||||||

| Motor | main.hook lifting | Model / kw | ZD,51-4/13(ZDS1.5/13) | |||||||

| Aux.hook lifting | D,32-4/4.5(ZDS0.4/4.5) | |||||||||

| crab travelling | ZDY(D),22-4/1.5×2 | |||||||||

| trolley travelling | ground | ZDY(D),22-4/1.5×2 | ZDY,31S4/2.2X2 | |||||||

| room | ZDR12L-4/2.1×2 | ZDR12L-4/3×2 | ||||||||

| Electric Hoist | CD,(MD₁) | |||||||||

| Lifting Height | m | 9;12;18 | ||||||||

| working system | A3-A5 | |||||||||

| Power source | 3-phase A.C;50Hz;380V | |||||||||

| trolley track recommended | 38KG/M | |||||||||

| Span | m | 7.5 | 10.5 | 13.5 | 16.5 | 19.5 | 22.5 | 25.5 | ||

| Max.wheel load | KN | 95 | 102 | 110 | 119 | 127 | 134 | 141 | ||

| Crane weight | ground controlling | kg | 7970 | 8610 | 9990 | 12800 | 15300 | 17540 | 20080 | |

| room controlling | kg | 8670 | 9310 | 10690 | 13500 | 16000 | 18240 | 20780 | ||

| Basic dimensions |

B | mm | 3500-5696 | |||||||

| W | mm | 3000-4200 | ||||||||

| Wc | mm | 2000-2400 | ||||||||

| K | mm | 1600-2250 | ||||||||

| H | mm | 1450 | 1650 | |||||||

| H1 | mm | 75 | 765 | |||||||

| H2 | mm | 265 | 365 | 465 | 370 | 470 | 570 | 670 | ||

| H3 | mm | 2490 | 2590 | 2690 | 2595 | 2695 | 2795 | 2895 | ||

| H4 | mm | -500 | -310 | |||||||

| b | mm | 120 | 230 | |||||||

| S1 | mm | 1240 | 900 | |||||||

| S2 | mm | 1450 | 1200 | |||||||

| QSWLGn rated lifting capacity | t | 10/3 | ||||||||

| operational method | m/min | ground controlling;room controlling | ||||||||

| Speed | main.hook lifting | 7(0.7/7) | ||||||||

| Aux.hook lifting | 8(0.8/8) | |||||||||

| crab travelling | 20 | |||||||||

| trolley travelling | ground | 20;30 | ||||||||

| room | 30;45 | |||||||||

| Motor | main.hook lifting | Model / kw | ZD,51-4/13(ZDS1.5/13) | |||||||

| Aux.hook lifting | ZD,32-4/4.5(ZDS0.4/4.5) | |||||||||

| crab travelling | ZDY(D),21-4/0.8×2 | |||||||||

| trolley travelling | ground | ZDY(D),22-4/1.5×2 | ||||||||

| room | ZDRI00-4(D)1.5×2 | ZDR12L-4/2.1×2 | ||||||||

| Eectric Hoist | CD₁ (MD₁) | |||||||||

| Lifting Height | m | 9;12;18;24 | ||||||||

| working system | A3-A5 | |||||||||

| Power source | 3-phase A.C.;50Hz;380V | |||||||||

| trolley track recommended | 38KG/M | |||||||||

| Span | m | 7.5 | 10.5 | 13.5 | 16.5 | 19.5 | 22.5 | 25.5 | ||

| Max.wheel load | KN | 65 | 72 | 77 | 80 | 88 | 97 | 102 | ||

| Crane weight |

ground controlling | kg | 6240 | 7600 | 8850 | 11200 | 14100 | 16400 | 19140 | |

| room controlling | kg | 6740 | 8300 | 9550 | 11900 | 14800 | 17100 | 19840 | ||

| Basic dimensions |

B | mm | 3500-5696 | |||||||

| W | mm | 3000-4200 | ||||||||

| Wc | mm | 2000-2400 | ||||||||

| K | mm | 1600-2250 | ||||||||

| H | mm | 1450 | 1650 | |||||||

| H1 | mm | 75 | 765 | |||||||

| H2 | mm | 165 | 265 | 315 | 415 | 320 | 420 | 520 | ||

| H3 | mm | 2390 | 2490 | 2540 | 2640 | 2545 | 2645 | 2745 | ||

| H4 | mm | 365 | 565 | |||||||

| b | mm | 120 | 230 | |||||||

| S1 | mm | 1250 | 900 | |||||||

| S2 | mm | 1400 | 1200 | |||||||

| QSWLGn rated lifting capacity | t | 32/10 | ||||||||

| operational method | m/min | ground controlling;room controlling | ||||||||

| Speed | man.hook lifting | 3(0.3/3) | ||||||||

| Aux.hook lifting | 7(7/0.7) | |||||||||

| crab travelling | 20 | |||||||||

| trolley travelling | ground | 20;30 | ||||||||

| room | 30;40 | |||||||||

| Motor | main.hook lifting | Model / kw | ZDX62-6/18.5,ZDS,2.2/18.5 | |||||||

| Aux.hook lifting | ZD,51-4/13(ZDS.5/13) | |||||||||

| crab travelling | ZDY,31S4/2.2×2 | |||||||||

| trolley travelling | ground | ZDY,31S4/2.2×2 ZDY,31-4/3×2 | ||||||||

| room | ZDRI2L-4/3.0×2 ZDR25-4/4.6×2 | |||||||||

| Bectric Hoist | WH64;CD,(MD₁) | |||||||||

| Lifting Height | m | 9:12:16;24 | ||||||||

| working system | A3-A5 | |||||||||

| Power source | 3-phase A.C;50Hz;380V | |||||||||

| trolley track recommended | 43KG/M | |||||||||

| Span | m | 7.5 | 10.5 | 13.5 | 16.5 | 19.5 | 22.5 | 25.5 | ||

| Max.wheel load | KN | 167 | 184 | 196 | 206 | 215 | 224 | 233 | ||

| Crane weight | ground contolling | kg | 12530 | 14660 | 16360 | 18870 | 21650 | 24260 | 27060 | |

| room controlling | kg | 13430 | 15560 | 17260 | 19770 | 22550 | 25160 | 27960 | ||

| Basic dimensions |

B | mm | 5070-5960 | 5572-6222 | ||||||

| W | mm | 3600-4500 | ||||||||

| Wc | mm | 2200-2900 | ||||||||

| K | mm | 1600-2500 | ||||||||

| H | mm | 1900 | ||||||||

| H1 | mm | 765 | ||||||||

| H2 | mm | 170 | 270 | 370 | 470 | 570 | 670 | 770 | ||

| H3 | mm | 2395 | 2495 | 2595 | 2695 | 2795 | 2895 | 2995 | ||

| H4 | mm | -700 | ||||||||

| b | mm | 230 | ||||||||

| S1 | mm | 1100 | ||||||||

| S2 | mm | 1600 | ||||||||

| QSWLGn rated lifting capacity | t | 20/5 | ||||||||

| operational method | m/min | ground controlling;room controlling | ||||||||

| Speed | main.hook lifting | 3.3 | ||||||||

| Aux.hook lifting | 8(0.8/8) | |||||||||

| crab travelling | 20 | |||||||||

| trolley travelling | ground | 20;30 | ||||||||

| room | 30;40 | |||||||||

| Motor | main.hook lifting | Model / kw | ZD,52-4/18.5 | |||||||

| Aux.hook lifting | ZD,41-4/7.5(ZDS0.8/7.5) | |||||||||

| crab travelling | ZDY(D)22-4/1.5×2 | |||||||||

| trolley travelling | ground | ZDY₁22-4/1.5×2 | ZDY,31S-4/2.2×2 | |||||||

| room | ZDR12L-4/3×2 | |||||||||

| Eectric Hoist | WH64;CD₁ (MD₁) | |||||||||

| Lifting Height | m | 6;12;18;24 | ||||||||

| working system | A3-A5 | |||||||||

| Power source | 3-phase A.C.;50Hz;380V | |||||||||

| trolley track recommended | 43KG/M | |||||||||

| Span | m | 7.5 | 10.5 | 13.5 | 16.5 | 19.5 | 22.5 | 25.5 | ||

| Max.wheel load | KN | 118 | 129 | 135 | 148 | 156 | 164 | 169 | ||

| Crane weight |

ground controlling | kg | 10500 | 11500 | 13640 | 15980 | 17700 | 20300 | 22920 | |

| room controlling | kg | 11200 | 12200 | 14340 | 16680 | 18400 | 21000 | 23620 | ||

| Basic dimensions |

B | mm | 4632-5982 | |||||||

| W | mm | 3750-4500 | ||||||||

| Wc | mm | 2310-2750 | ||||||||

| K | mm | 1600-2500 | ||||||||

| H | mm | 1790 | ||||||||

| H1 | mm | 765 | ||||||||

| H2 | mm | 170 | 270 | 370 | 520 | 620 | ||||

| H3 | mm | 2395 | 2495 | 2595 | 2745 | 2845 | ||||

| H4 | mm | -350 | ||||||||

| b | mm | 230 | ||||||||

| S1 | mm | 1100 | ||||||||

| S2 | mm | 1100 | ||||||||

| QSMLGn rated lifting capacity | t | 16/3 | ||||||||

| operational method | m/min | ground controlling;room controlling | ||||||||

| Speed | main.hook lifting | 3.5(0.35/3.5) | ||||||||

| Aux.hook lifting | 8(0.8/8) | |||||||||

| crab travelling | 20 | |||||||||

| trolley travelling | ground | 20;30 | ||||||||

| room | 30;45 | |||||||||

| Motor | main.hook lifting | Model / kw | ZD,51-4/13(ZDS1.5/13) | |||||||

| Aux.hook lifting | D,32-4/4.5(ZDS0.4/4.5) | |||||||||

| crab travelling | ZDY(D),22-4/1.5×2 | |||||||||

| trolley travelling | ground | ZDY(D),22-4/1.5×2 | ZDY,31S4/2.2X2 | |||||||

| room | ZDR12L-4/2.1×2 | ZDR12L-4/3×2 | ||||||||

| Electric Hoist | CD,(MD₁) | |||||||||

| Lifting Height | m | 9;12;18 | ||||||||

| working system | A3-A5 | |||||||||

| Power source | 3-phase A.C;50Hz;380V | |||||||||

| trolley track recommended | 38KG/M | |||||||||

| Span | m | 7.5 | 10.5 | 13.5 | 16.5 | 19.5 | 22.5 | 25.5 | ||

| Max.wheel load | KN | 95 | 102 | 110 | 119 | 127 | 134 | 141 | ||

| Crane weight | ground controlling | kg | 7970 | 8610 | 9990 | 12800 | 15300 | 17540 | 20080 | |

| room controlling | kg | 8670 | 9310 | 10690 | 13500 | 16000 | 18240 | 20780 | ||

| Basic dimensions |

B | mm | 3500-5696 | |||||||

| W | mm | 3000-4200 | ||||||||

| Wc | mm | 2000-2400 | ||||||||

| K | mm | 1600-2250 | ||||||||

| H | mm | 1450 | 1650 | |||||||

| H1 | mm | 75 | 765 | |||||||

| H2 | mm | 265 | 365 | 465 | 370 | 470 | 570 | 670 | ||

| H3 | mm | 2490 | 2590 | 2690 | 2595 | 2695 | 2795 | 2895 | ||

| H4 | mm | -500 | -310 | |||||||

| b | mm | 120 | 230 | |||||||

| S1 | mm | 1240 | 900 | |||||||

| S2 | mm | 1450 | 1200 | |||||||

|

QSWLGn rated lifting capacity |

t |

10/3 |

||||||||

|

operational method |

m/min |

ground controlling;room controlling |

||||||||

|

Speed |

main.hook lifting |

7(0.7/7) |

||||||||

|

Aux.hook lifting |

8(0.8/8) |

|||||||||

|

crab travelling |

20 |

|||||||||

|

trolley travelling |

ground |

20;30 |

||||||||

|

room |

30;45 |

|||||||||

|

Motor |

main.hook lifting |

Model / kw |

ZD,51-4/13(ZDS1.5/13) |

|||||||

|

Aux.hook lifting |

ZD,32-4/4.5(ZDS0.4/4.5) |

|||||||||

|

crab travelling |

ZDY(D),21-4/0.8×2 |

|||||||||

|

trolley travelling |

ground |

ZDY(D),22-4/1.5×2 |

||||||||

|

room |

ZDRI00-4(D)1.5×2 |

ZDR12L-4/2.1×2 |

||||||||

|

Eectric Hoist |

CD₁ (MD₁) |

|||||||||

|

Lifting Height |

m |

9;12;18;24 |

||||||||

|

working system |

A3-A5 |

|||||||||

|

Power source |

3-phase A.C.;50Hz;380V |

|||||||||

|

trolley track recommended |

38KG/M |

|||||||||

|

Span |

m |

7.5 |

10.5 |

13.5 |

16.5 |

19.5 |

22.5 |

25.5 |

||

|

Max.wheel load |

KN |

65 |

72 |

77 |

80 |

88 |

97 |

102 |

||

|

Crane |

ground controlling |

kg |

6240 |

7600 |

8850 |

11200 |

14100 |

16400 |

19140 |

|

|

room controlling |

kg |

6740 |

8300 |

9550 |

11900 |

14800 |

17100 |

19840 |

||

|

Basic |

B |

mm |

3500-5696 |

|||||||

|

W |

mm |

3000-4200 |

||||||||

|

Wc |

mm |

2000-2400 |

||||||||

|

K |

mm |

1600-2250 |

||||||||

|

H |

mm |

1450 |

1650 |

|||||||

|

H1 |

mm |

75 |

765 |

|||||||

|

H2 |

mm |

165 |

265 |

315 |

415 |

320 |

420 |

520 |

||

|

H3 |

mm |

2390 |

2490 |

2540 |

2640 |

2545 |

2645 |

2745 |

||

|

H4 |

mm |

365 |

565 |

|||||||

|

b |

mm |

120 |

230 |

|||||||

|

S1 |

mm |

1250 |

900 |

|||||||

|

S2 |

mm |

1400 |

1200 |

|||||||

| QSWLGn rated lifting capacity | t | 5 | |||||||||

| operational method | m/min | ground controlling;room controlling | |||||||||

| Speed | main.hook lifting | 8(0.8/8) | |||||||||

| Aux.hook lifting | |||||||||||

| crab travelling | 20 | ||||||||||

| trolley travelling | ground | 20;30 | |||||||||

| room | 30;45 | ||||||||||

| Motor | main.hook lifting | Model / kw | ZD,41-4(ZDS0.817.5) | ||||||||

| Aux.hook lifting | |||||||||||

| crab travelling | ZDY(D)₁21-4/0.8×2 | ||||||||||

| trolley travelling | ground | ZDY(D),21-4/0.8×2 | ZDY(D),22-4/1.5×2 | ||||||||

| room | ZDR100-4(D)1.5×2 | ZDR12L-4/2.1×2 | |||||||||

| ectric Hoist | CD₁ (MD₁) | ||||||||||

| Lifting Height | m | 6;9;12;18;24;30; | |||||||||

| working system | A3-A5 | ||||||||||

| Power source | 3-phase A.C;50Hz;380V | ||||||||||

| trolley track recommended | 38KG/M | ||||||||||

| Span | m | 7.5 | 10.5 | 13.5 | 16.5 | 19.5 | 22.5 | 25.5 | |||

| Max.wheel load | KN | 39 | 43 | 48 | 53 | 59 | 62 | 71 | |||

| Crane weight |

ground controlling | kg | 5230 | 6400 | 7450 | 8600 | 10560 | 12350 | 14850 | ||

| room controling | kg | 5730 | 7100 | 8150 | 9300 | 11260 | 13050 | 15550 | |||

| Basic dimensions |

B | mm | 3200-3900 | 3700-4200 | 5300 | ||||||

| W | mm | 2700-3100 | 3200-3600 | 3800 | |||||||

| Wc | mm | 1200-1500 | |||||||||

| K | mm | 1400-1800 | |||||||||

| H | mm | 1350 | 1550 | ||||||||

| H1 | mm | 75 | 765 | ||||||||

| H2 | mm | 165 | 265 | 365 | 465 | 370 | |||||

| H3 | mm | 2390 | 2490 | 2590 | 2690 | 2595 | |||||

| H4 | mm | 385 | 540 | ||||||||

| b | mm | 120 | 230 | ||||||||

| S1 | mm | 1200 | 1200 | ||||||||

| S2 | mm | 1200 | 1200 | ||||||||

We are an integrated industrial and trade enterprises. We have our own R&D team, factory and marketing department.

Our Crane can design and manufacture base on FEM, ISO EN, GB standard.

All our processes strictly adhere to ISO-9001 procedures, which include Material Traceability, ISO WPQR and welder certificate, Measuring Device Calibration, NDT for the welding, and full assembling and load testing before delivery.

We accept T/T bank transfer, Paypal.

We suggest you to recruit a crane service team in local to install the crane base on our Installation Guideline and User manual. If cannot, we can send engineer to your factory to guide you do the installation with extra charge, and the transportation, accommodation, translator shall be covered by your side also.