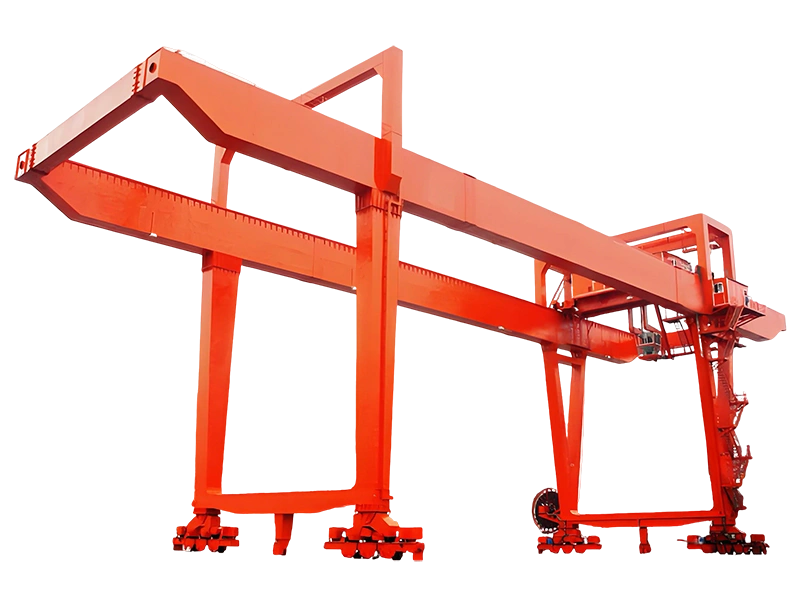

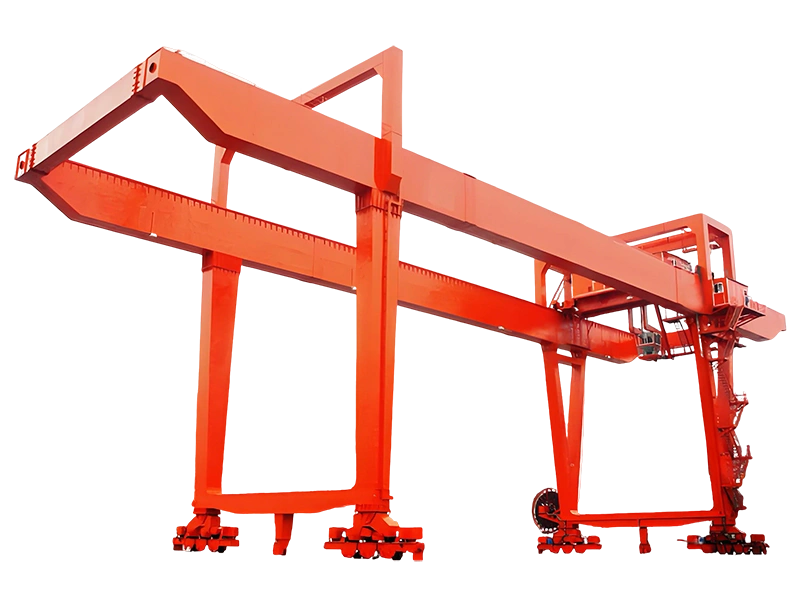

Gantry crane with shield(DMG for short)is mainly used for installation of cutter andshield of shield machine which is underground trenchless device,and used for lifting of ductpiece supporting tunnel during work progress.DMG has stable performance,high productionefficiency and is easy to be taken care of and maintained.The lifting appliance at upper partcan turn to adapt the requirements of tunneling at different dire ctions.It has flexible operatingmode,complete safety in dication and overload protecti on device,which can uttermost ensurethe safety of operator and equipments.Electrical system adopts PLC variable frequency speedregulating which is ProPitious to control the mechanisms.Famous manufacturer of fittingsisadopted to guarantee thequality of the complete machine.The latest issued national standardsare executed for design,manufacture and inspection of DMG.

1.The power of crane is three-phase AC;rated frequency is 50HZ;rated voltage is 380V;

2.The temperature of working environment is -20~+45℃;the max.relative humidity isno less than 95%(there is condensation);

3.Wind speed during work is no more than 20m/s;

4.Working class of the crane is A3,A4;

5.The crane that has special requirements for environmental conditions shall execute thecontract articles.

| (t)Lifting capactiy | 400 | |||

| Working system | A3 | |||

| S Span | 33 | 34 | ||

| Lifting Height | (m)Main lifting | 24(top rail)23(bottom rail) | 24(top rail)23(bottom rail) | |

| (m)Aux lifting | 22(top rail)26(bottom rail) | 22(top rail)26(bottom rail) | ||

| spend | lifting | (m/min)Main lifting | 0.09~0.9 | 0.09~0.9 |

| (m/min)Aux lifting | 7 | 7 | ||

| travelling | crane travelling | 1.6~16 | 1.6~16 | |

| trolley travelling | 1.15~11.5 | 1.15~11.5 | ||

| (mm) Dimensions |

L1 | 2500 | ||

| L2 | 3500 | |||

| H1 | 3196 | |||

| H2 | 22000 | |||

| B | 14000 | |||

| B1 | 22800 | |||

| b1 | 1920 | |||

| b2 | 1250 | |||

| W | 4500 | |||

| D | 6000 | |||

| (KN)Max wheel load | 406 | 415 | ||

| Steel track | QU120 | |||

| Power source | 50Hz 380V | |||

| Rotation angle of lifting device ±90° | ||||

| Maximum applicable cutterhead diameter (m) 15 | ||||

| (t)Lifting capactiy | 400 | |||

| Working system | A3 | |||

| S Span | 33 | 34 | ||

| Lifting Height | (m)Main lifting | 22(top rail)23(bottom rail) | 22(top rail)23(bottom rail) | |

| (m)Aux lifting | 20(top rail)26(bottom rail) | 20(top rail)26(bottom rail) | ||

| spend | lifting | (m/min)Main lifting | 0.09~0.9 | 0.09~0.9 |

| (m/min)Aux lifting | 7 | 7 | ||

| travelling | crane travelling | 1.6~16 | 1.6~16 | |

| trolley travelling | 1.15~11.5 | 1.15~11.5 | ||

| (mm) Dimensions |

L1 | 2500 | ||

| L2 | 3500 | |||

| H1 | 3196 | |||

| H2 | 20000 | |||

| B | 13000 | |||

| B1 | 21800 | |||

| b1 | 1850 | |||

| b2 | 1190 | |||

| W | 4500 | |||

| D | 7160 | |||

| (KN)Max wheel load | 401 | 412 | ||

| Steel track | QU120 | |||

| Power source | 50Hz 380V | |||

| Maximum applicable cutterhead diameter (m) 15 | ||||

| (t)Lifting capactiy | 180/30+180/30 | ||

| Working system | A4 | ||

| S Span | 24 | ||

| Lifting Height | (m)Main lifting | 22(top rail)52(bottom rail) | |

| (m)Aux lifting | 23(top rail)52(bottom rail) | ||

| spend | lifting | (m/min)Main lifting | 0.25~2.5 |

| (m/min)Aux lifting | 1~10 | ||

| travelling | crane travelling | 1.6~16 | |

| trolley travelling | 2~20 | ||

| (mm) Dimensions |

L1 | 4000 | |

| L2 | 4000 | ||

| H1 | 3000 | ||

| H2 | 23000 | ||

| B | 12000 | ||

| B1 | 19028 | ||

| b1 | 1600 | ||

| b2 | 760 | ||

| W | 4000 | ||

| D | 5800 | ||

| (KN)Max wheel load | 396 | ||

| Steel track | QU100 | ||

| Power source | 50Hz 380V | ||

| Lifting device rotation angle | ±90° | ||

| Maximum applicable cutterhead diameter (m) | 13.2 | ||

| (t)Lifting capactiy | 150/50+150 | ||

| Working system | A3 | ||

| S Span | 20 | ||

| Lifting Height | (m)Main lifting | 15 | |

| (m)Aux lifting | 16 | ||

| spend | lifting | (m/min)Main lifting | 0.3~3 |

| (m/min)Aux lifting | 6 | ||

| travelling | erane travelling | 2~20 | |

| trolley travelling | 2.5~25 | ||

| (mm) Dimensions |

L1 | 3500 | |

| L2 | 1500 | ||

| H1 | 16000 | ||

| B | 9000 | ||

| B1 | 14154 | ||

| b1 | 1350 | ||

| b2 | 1350 | ||

| W | 4000 | ||

| D | 3000 | ||

| (KN)Max wheel load | 400 | ||

| Steel track | QU80 | ||

| Power source | 50Hz 380V | ||

| Maximum applicable cutterhead diameter (m) | 10.2 | ||

| (t)Lifting capactiy | 100+100 | |||

| Working system | A4 | |||

| S Span | 33 | 34 | ||

| Lifting Height | (m)Main lifting | 15(top rail)21(under the track) | 15(top rail)21(under the track) | |

| spend | lifting | (m/min)Main lifting | 0.3~3.6 | 0.3~3.6 |

| travelling | crane travelling | 2~20 | 2~20 | |

| trolley travelling | 2.5~25 | 2.5~25 | ||

| (mm) Dimensions |

L1 | 2320 | ||

| L2 | 4000 | |||

| H1 | 1720 | |||

| B | 12000 | |||

| B1 | 19100 | |||

| b1 | 1850 | |||

| b2 | 6500 | |||

| W | 5000 | |||

| D | 3000 | |||

| (KN)Max wheel load | 298 | 317 | ||

| Steel track | QU100 | |||

| Power source | 50Hz 380V | |||

| Maximum applicable cutterhead diameter (m) 13 | ||||

| (t)Lifting capactiy | 100+100 | |||

| Working system | A4 | |||

| S Span | 33 | 34 | ||

| Lifting Height | (m)Main lifting | 15(top rai)21(bottom rail)) | 15(top rai)21(bottom rail)) | |

| spend | lifting | (m/min)Main lifting | 0.3~3.6 | 0.3~3.6 |

| travelling | crane travelling | 2~20 | 2~20 | |

| trolley travelling | 2.5~25 | 2.5~25 | ||

| (mm) Dimensions |

L1 | 2320 | ||

| L2 | 2320 | |||

| H1 | 1720 | |||

| B | 12000 | |||

| B1 | 19100 | |||

| b1 | 6500 | |||

| b2 | 1850 | |||

| W | 1050 | |||

| D | 3000 | |||

| (KN)Max wheel load | 278 285 | |||

| Steel track | QU100 | |||

| Power souree | 50Hz 380V | |||

| Maximum applicable cutterhead diameter (m) 13 | ||||

| (t)Lifting capactiy | 130 | ||||

| Working system | A4 | ||||

| S Span | 20 | 22 | 24 | ||

| Lifting Height | (m)Main lifting | 10(top rail)30(bottom rail) | 10(top rail)30(bottom rail) | 10(top rail)30(bottom rail) | |

| spend | lifting | (m/min)Main lifting | 0.37~3.7~6 | 0.37~3.7~6 | 0.37~3.7~6 |

| travelling | crane travelling | 1.4~14 | 1.4~14 | 1.4~14 | |

| trolley travelling | 2.5~25 | 2.5~25 | 2.5~25 | ||

| (mm) Dimensions |

L1 | 1750 | |||

| L2 | 1910 | ||||

| H1 | 1020 | ||||

| B | 10500 | ||||

| B1 | 16180 | ||||

| b1 | 1250 | ||||

| b2 | 1250 | ||||

| W | 6500 | ||||

| D | 3000 | ||||

| (KN)Max wheel load | 275 | 283 | 295 | ||

| Steel track | QU80 | ||||

| Power source | 50Hz 380V | ||||

| Maximum applicable cutterhead diameter (m) 6.3 | |||||

| (t)Lifting capactiy | 100 | ||||

| Working system | A4 | ||||

| S Span | 20 | 22 | 24 | ||

| Lifting Height | (m)Main lifting | 10(top rail)30(bottom rail) | 10(top rail)30(bottom rail) | 10(top rail)30(bottom rail) | |

| spend | lifting | (m/min)Main lifting | 0.37~3.7~6 | 0.37~3.7~6 | 0.37~3.7~6 |

| travelling | erane travelling | 1.4~14 | 1.4~14 | 1.4~14 | |

| trolley travelling | 2.5~25 | 2.5~25 | 2.5~25 | ||

| (mm) Dimensions |

L1 | 1750 | |||

| L2 | 1900 | ||||

| H1 | 1020 | ||||

| B | 10700 | ||||

| B1 | 16400 | ||||

| b1 | 1270 | ||||

| b2 | 1270 | ||||

| W | 6500 | ||||

| D | 3000 | ||||

| (KN)Max wheel load | 244 | 252 | 258 | ||

| Steel track | QU80 | ||||

| Power source | Three-phase alternating current50Hz 380V | ||||

| Maximum applicable cutterhead diameter (m) 6.3 | |||||

We are an integrated industrial and trade enterprises. We have our own R&D team, factory and marketing department.

Our Crane can design and manufacture base on FEM, ISO EN, GB standard.

All our processes strictly adhere to ISO-9001 procedures, which include Material Traceability, ISO WPQR and welder certificate, Measuring Device Calibration, NDT for the welding, and full assembling and load testing before delivery.

We accept T/T bank transfer, Paypal.

We suggest you to recruit a crane service team in local to install the crane base on our Installation Guideline and User manual. If cannot, we can send engineer to your factory to guide you do the installation with extra charge, and the transportation, accommodation, translator shall be covered by your side also.