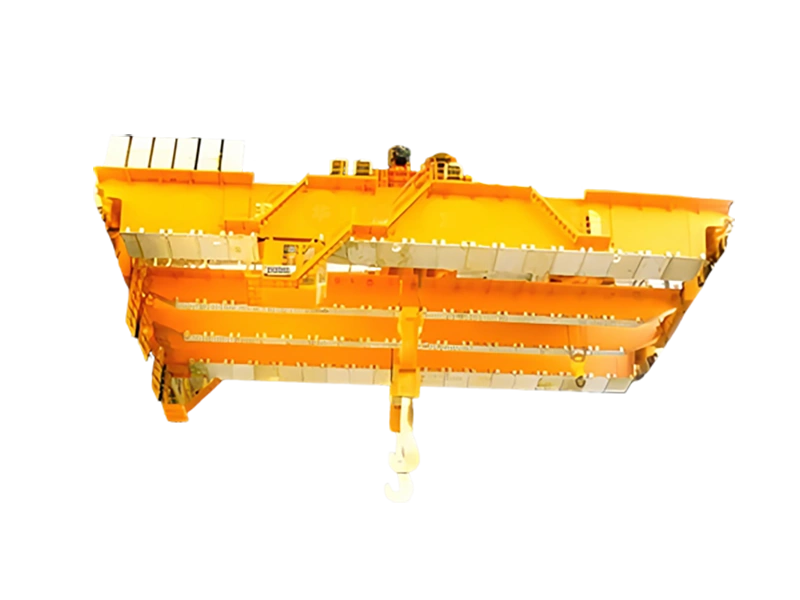

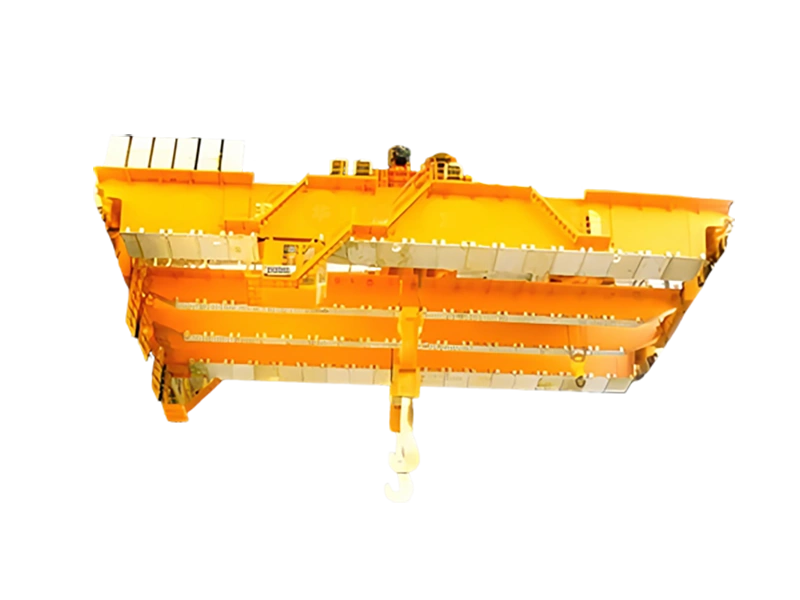

Foundry crane is one of the main equipments in the continuous casting technology of steelmaking.It is mainly used for pouring melted ir on from additive bay of converter to converter;lifting molten steel from refining bay to refining furnace or lifting molten steel from molten steel bay to ladle turret of continuous Casting machine.

The overall structure of foundry crane has the following forms:two-girder and two-rail,four-girder and

four-rail,and four-girder and six-rail,etc.The form oftwo-girder and two-rail,and four-girder and four-rail

are mainly used for middle and large-tonnage foundry crane;the form of four-gir der and six-rail and two- trolley is mainly used for extra large-tonnage foundry crane.

The foundry crane is one of Qilide's leading products.The company designed and

manufactured the foundry crane technology, advanced technology,novel structure, safe

and reliable,economic and durable,simple maintenance.The foundry cranes manufactured by Qilide can be supplied as follows upon request.

1.The mechanisms can be speed governing(1:10 or larger);

2.The lifting appliances are rotatable;

3.The spacing of portal hook is variable;

4.Limit and warning for over load;

5.Weighing and display ofload,PLC control and failure detection,display,record and printing system;

6.Prevent collision between cranes of same span.

| (t)Lifting capactiy | 100/32 | 125/32 | ||||

| Working Class | A7 | A7 | ||||

| S(m)Span | 19 | 22 | 25 | 19 | 22 | |

| (m) Lifting Height | Main hook | 18 | 20 | 25 | 24 | 20 |

| Auxiliary hook | 20 | 22 | 27 | 26 | 22 | |

| Speed | Main hook | 6.8 | 6.8 | 8.6 | 9.5 | 7.6 |

| Auxiliary hook | 9.5 | 9.5 | 12 | 12 | 9.5 | |

| trolley | 37 | 37 | 41 | 42 | 36 | |

| crane | 68 | 68 | 77 | 77 | 77 | |

| (mm) Dimensions |

H | 4900 | 4900 | 5100 | 5150 | 5200 |

| H1 | 4500 | 4500 | 5000 | 5000 | 5000 | |

| H2 | 1200 | 1200 | 1300 | 1350 | 1350 | |

| B | 13500 | 13800 | 14800 | 14800 | 14800 | |

| B1 | 7800 | 8000 | 9000 | 9000 | 9000 | |

| b | 410 | 410 | 410 | 410 | 410 | |

| limt dimenstion |

H3 | 3500 | 3500 | 3500 | 380 | 380 |

| H4 | 1200 | 1200 | 1200 | 1200 | 1200 | |

| S1 | 2000 | 2000 | 2000 | 2200 | 2200 | |

| S2 | 3700 | 3700 | 3700 | 4100 | 4100 | |

| S3 | 4100 | 4100 | 4100 | 4700 | 4700 | |

| S4 | 1600 | 1600 | 1600 | 1600 | 1600 | |

| (KN)Maxwheel load | 520 | 530 | 545 | 580 | 595 | |

| Steel track Recommended | QU120 | QU120 | QU120 | QU120 | QU120 | |

| Power source | 380V 50HZ 3-Phase A .C . 380V 50HZ | |||||

| (t)Lifting capactiy | 125/32 | 140/32 | |

| Working Class | A7 | A7 | |

| S(m)Span | 19 | 19 | |

| (m) Lifting Height | Main hook | 24 | 22 |

| Auxiliary hook | 26 | 24 | |

| Speed | Main hook | 7.6 | 7.8 |

| Auxiliary hook | 12 | 9.7 | |

| Main trolley | 38 | 36 | |

| Auxiliary trolley | 39 | 37.5 | |

| crane | 76 | 73 | |

| (mm) Dimensions |

H | 5690 | 5880 |

| H1 | 5500 | 5600 | |

| H2 | 1350 | 1350 | |

| B | 15800 | 15800 | |

| B1 | 10120 | 10100 | |

| B2 | 2800 | 2500 | |

| limt dimenstion |

b | 410 | 450 |

| H3 | 4200 | 4350 | |

| H4 | 1300 | 1500 | |

| S1 | 2200 | 2300 | |

| S2 | 2000 | 2000 | |

| S3 | 1500 | 1500 | |

| S4 | 1500 | 1600 | |

| (KN)Maxwheel load | 505 | 535 | |

| Steel track Recommended | QU120 | QU120 | |

| Power source | 380V 50HZ 3-Phase A.C. 380V 50HZ | ||

| (t)Lifting capactiy | 160/32 | |

| Working Class | A7 | |

| S(m)Span | 27 | |

| (m) Lifting Height | Main hook | 25 |

| Auxiliary hook | 26 | |

| speed | Main hook | 9.8 |

| Auxiliary hook | 12 | |

| Main trolley | 43.5 | |

| Auxiliary trolley | 43.5 | |

| crane | 84 | |

| (mm) Dimensions |

H | 6350 |

| H1 | 2700 | |

| H2 | 1250 | |

| B | 16800 | |

| B1 | 10800 | |

| B2 | 3300 | |

| limt dimenstion |

b | 550 |

| H3 | 6000 | |

| H4 | 1100 | |

| S1 | 2800 | |

| S2 | 2650 | |

| S3 | 1800 | |

| S4 | 2200 | |

| (KN)Maxwheel load | 485 | |

| Steel track Recommended | QU120 | |

| Power source | 380V 50HZ 3-Phase A .C . 380V 50HZ | |

| (t)Lifting capactiy | 180/50 | 200/50 | 225/65 | 240/80 | ||

| Working Class | A7 | A7 | A7 | A7 | ||

| S(m)Span | 28.5 | 28 | 27 | 22 | ||

| (m) Lifting Height | Main hook | 27 | 26 | 32 | 25 | |

| Auxiliary hook | 29 | 26 | 34 | 27 | ||

| Speed | Main hook | 7.5 | 6 | 11 | 7 | |

| Auxiliary hook | 10 | 10 | 11 | 9.6 | ||

| Main trolley | 40 | 41 | 41 | 35 | ||

| Auxiliary trolley | 38 | 38 | 39.5 | 38 | ||

| crane | 80 | 78 | 84 | 80 | ||

| (mm) Dimensions |

H | 6850 | 6900 | 7000 | 7000 | |

| H1 | 5860 | 6000 | 5990 | 5650 | ||

| H2 | 1350 | 1650 | 1400 | 1350 | ||

| B | 17500 | 17000 | 17300 | 18500 | ||

| B1 | 10500 | 10000 | 10100 | 11250 | ||

| B2 | 3500 | 3200 | 3300 | 3800 | ||

| limt dimenstion |

b | 4500 | 450 | 450 | 450 | |

| H3 | 5500 | 6000 | 5800 | 5500 | ||

| H4 | 1200 | 1000 | 1000 | 1500 | ||

| S1 | 2450 | 2600 | 2500 | 2800 | ||

| S2 | 3000 | 3000 | 3000 | 3200 | ||

| S3 | 2000 | 2000 | 2200 | 2400 | ||

| S4 | 1600 | 1600 | 1600 | 2800 | ||

| (KN)Max wheel load | 525 | 530 | 550 | 545 | ||

| Steel track Recommended | QU120 | QU120 | QU120 | Qu120 | ||

| Power source | 380V 50HZ 3-Phase A .C . 380V 50HZ | |||||

| (t)Lifting capactiy | 280/65 | 320/80 | |

| Working Class | A7 | A7 | |

| Sm)San | 21 | 24.5 | |

| (m) Lifting Height |

Main hook | 24 | 28 |

| Auxiliary hook | 26 | 32 | |

| speed | Man hook | 10 | 7.5 |

| Auxiliary hook | 12 | 10 | |

| Main trolley | 30 | 29 | |

| Auxiliary trolley | 39 | 39 | |

| crane | 76 | 58 | |

| (mm) Dimensions |

H | 7600 | 7800 |

| H1 | 6400 | 6500 | |

| H2 | 1350 | 1500 | |

| B | 19200 | 19500 | |

| B1 | 12000 | 12500 | |

| B2 | 3800 | 5000 | |

| limt dimenstion |

b | 500 | 500 |

| H3 | 5900 | 6000 | |

| H4 | 1500 | 1700 | |

| S1 | 3200 | 3300 | |

| S2 | 3500 | 3500 | |

| S3 | 2400 | 2600 | |

| S4 | 2800 | 3000 | |

| (KN)Maxwheel load | 595 | 650 | |

| Seel track Recommended | QU120 | QU120 | |

| Power source | 380V 50HZ 3-Fa se A.C.380V 50HZ | ||

| Performance Parameters | S (m)Span |

10.5m | 13.5m | 16.5m | 19.5m | 22.5m | 25.5m | 28.5m | 31.5m | 10.5m | 13.5m | 16.5m | 19.5m | 22.5m | 25.5m | 28.5m | 31.5m |

| (t) Lifting capactiy |

(80t)Main hook (20t)Auxiliary hook | (100t)Main hook (20t)Auxiliary hook | |||||||||||||||

| (m) Lifting Height |

(28m)Main hook (30m)Auxiliary hook | (24m)Main hook (30m)Auxiliary hook | |||||||||||||||

| Hoisiing speed | 0.15~1.5m/min Main hook 0.63~6.3m/min Auxiliary hook | 0.15~1.5m/min Main hook 0.63~6.3m/min Auxiliary hook | |||||||||||||||

| Travel speed | 1.5~15m/min Crab travelling 2~30m/min The Crane travelling | 1.5~15m/min Crab travelling2~30m/minThe Crane travelling | |||||||||||||||

| Working system | A3 | A3 | |||||||||||||||

| Installed power | 57.5kn | 61.5kn | 75.5kn | 82.5kn | |||||||||||||

| Maxwheel load | 231kn | 245kn | 256kn | 266kn | 272kn | 278kn | 288kn | 296kn | 286kn | 298kn | 308kn | 315kn | 320kn | 328kn | 340kn | 349kn | |

| (mm)Dmensions | H | 2196mm | 2462mm | ||||||||||||||

| H1 | 302mm | 304mm | 404mm | 654mm | 656mm | 756mm | 956mm | 958mm | 402mm | 404mm | 504mm | 656mm | 658mm | 758mm | 958mm | 990mm | |

| H2 | 2802mm | 2804mm | 2904mm | 3154mm | 3156mm | 3256mm | 3456mm | 3458mm | 2902mm | 2904mm | 3004mm | 3156mm | 3158mm | 3258mm | 3458mm | 3460mm | |

| H3 | 350mm | 400mm | |||||||||||||||

| H4 | 330mm | 450mm | |||||||||||||||

| H5 | 50mm | 200mm | |||||||||||||||

| L | 872mm | 958mm | |||||||||||||||

| L1 | 850mm | 850mm | |||||||||||||||

| L2 | 1850mm | 1850mm | |||||||||||||||

We are an integrated industrial and trade enterprises. We have our own R&D team, factory and marketing department.

Our Crane can design and manufacture base on FEM, ISO EN, GB standard.

All our processes strictly adhere to ISO-9001 procedures, which include Material Traceability, ISO WPQR and welder certificate, Measuring Device Calibration, NDT for the welding, and full assembling and load testing before delivery.

We accept T/T bank transfer, Paypal.

We suggest you to recruit a crane service team in local to install the crane base on our Installation Guideline and User manual. If cannot, we can send engineer to your factory to guide you do the installation with extra charge, and the transportation, accommodation, translator shall be covered by your side also.